Research & Design

R&D

Establishment & Verification of Quality Spec.

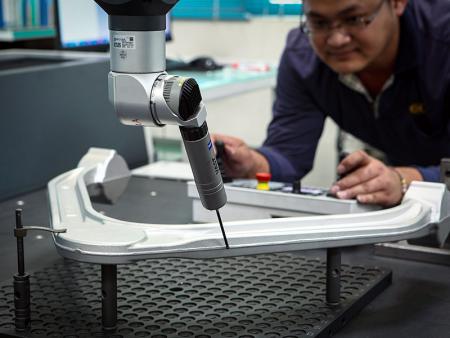

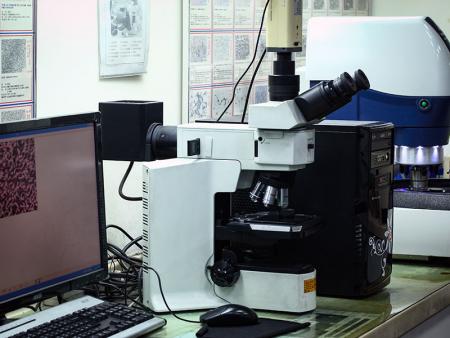

Always adhering to our core values and corporate culture for "Customer Satisfaction" and "Safety First", the establishment of quality specification for a new product starts form collecting the design parameters of the original manufacturer. By using advanced instruments to measure and test the OE samples, we discover not only the dimensional parameters but also its physical characteristics so as to approach as close as the OE quality.

Secondly, technical drawings and quality spec. are established on the basis of parameters collected from OE sample. Then, some initial samples will be prepared by engineers for quality verification. Quality verification is conducted by exactly the same measurements, the same static and dynamic test conditions as we did to the OE sample earlier.

For the quality verification and approval of a new product, we have dynamic simulation test laboratory. By "dynamic functional test", we could figure out how close we approached to the OE quality standard in functional aspect. One the other hand, the "dynamic durability test" helps us to predict how long the service life of a new developed product will be, and how to modify it for longer durability.

Design & Production of Moulds and Products

To collect the 3D digital parameters of the original design, we scan the OE sample by using a reverse engineering scanner. Then create 2D / 3D drawings of the product and mold design through CAD program. Further, computer-aided manufacturing program CAM is used to make related moulds and fixtures.

In the way, the shape, dimensions and angles of the control arm samples made by OE can be accurately reproduced almost without difference. And therefore, ensure the new developed control arm can be installed on the vehicle frame properly and quickly.

Equipment's

- CMM

- Oscillating Disc Rheometer

- Mooney Viscometer

- Metallographic Microscope

- Universal Testing Machine

Press Release

BMW 7 Series E38

BMW 7 Series E38Full set suspension control arm products, 7 series, E38 1995 ~ 2001.

Read More BMW 5 Series F10

BMW 5 Series F10Full set suspension control arm products, 5 series, F10 2010~, 6 series. F06 2010~

Read More Mercedes Benz S-Class

Mercedes Benz S-ClassFull set suspension control arm products, S-Class W211 2002 ~ 2009.

Read More