Ball Joint Dynamic Functional & Durability

Static Pull Out Strength Test

Ball joint links wheel and control arm. When the vehicle is traveling and steered at high speed, the force applied on the ball joint of control arm could be as high as ten thousand newtons. If the structural strength of the ball joint is not strong enough, the ball pin may be pulled out of its housing, resulting in disconnection of wheel from the control arm. This is very dangerous! Because the vehicle will be completely out of control if it occurs. Therefore, the pull-out strength of the ball pin is the key quality to ensure safe driving.

There are several important parameters for the design of a ball joint. They are the materials used for the ball stud and its housing, the dimensional & structural design, lubricant. The plastic material for the inner socket is also important, it must be good abrasion resistant for longer durability.

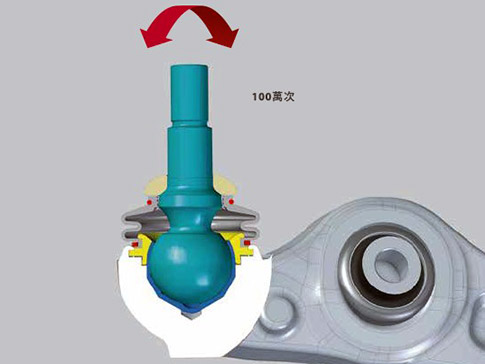

Dynamic Rotation Torque Attenuation Test

When the vehicle is in motion, the control arm ball joint functions as a "universal joint". Accompanied with the up and down and steering movements of the wheel, the movements of the ball against the inner socket could be rotation, or sway, or rotation plus sway. The plastic socket wears day after day, and the tightness between the ball pin and the socket gets looser and looser. Eventually lead to a clearance formed between the ball and socket. As a result, it makes a clicking, popping, or snapping sound when the wheel is turned, and finally turns into a squeaking sound at the end of a stop.

Such problem caused by the wear of socket is not easy to be noticed. The safest way is to have your control arm ball joint checked each time when your car back to repair shop for regular maintenance.

Dynamic Swing Reciprocation Attenuation Test

The parameter used to measure the tightness of a ball joint is the torque of ball pin against its inner socket. Car manufactures always have torque specifications for ball joints with different ball diameters.

The durability of a ball joint with too high or too low torque value will be poor. It is better to just simply follow the OE standard value collected by measuring OE samples.

The structure of control arm ball join is similar to the limb joint of human. The components inside the joint always work in a mutual sliding friction way. Therefore, it must be well lubricated with grease.

If the grease is deteriorated or lost, the plastic socket will wear very quickly and cause the problems of abnormal sounds and misalignment of wheels.

Press Release

BMW 7 Series E38

BMW 7 Series E38Full set suspension control arm products, 7 series, E38 1995 ~ 2001.

Read More BMW 5 Series F10

BMW 5 Series F10Full set suspension control arm products, 5 series, F10 2010~, 6 series. F06 2010~

Read More Mercedes Benz S-Class

Mercedes Benz S-ClassFull set suspension control arm products, S-Class W211 2002 ~ 2009.

Read More